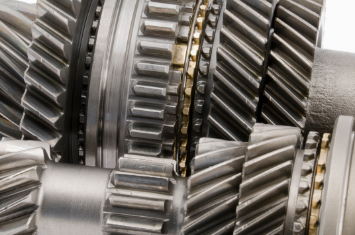

Heat treatment is a small part of your total manufacturing costs, however, these costs can increase significantly when quality issues arise and corrective processes must be implemented. Avoid this and find your competitive edge with the right system, expert support and a reliable gas supply from Airgas, an Air Liquide company.

As a leading supplier of gases and equipment solutions for heat treatment of metal, we can help provide a clean atmosphere for your heat treatment processes and a safe environment for your workforce.

From wasted materials to wasted effort, a suboptimal process can lead to a lot of unnecessary costs. That’s why Airgas takes an in-depth look at your heat treatment process, helping you improve quality, safety and cycle times. Talk to Airgas if you’re facing any of these challenges:

Are you ready to improve quality, safety and cycle times with minimal or no cost impact?

Then choose Airgas, a leading supplier of gases and equipment solutions for heat treating metal. We can help provide a clean atmosphere for your process and a safer environment for your workforce.

Get started. Contact us today by requesting a follow-up or calling 800‑282‑1524.

Backed by decades of experience in heat treatment, we can help you implement improvements that will have a lasting impact on the health of your business. From the chart below, see how we can help you adapt your process to improve quality requirements (with minimal or no cost impact), reduce cycle times to achieve greater throughput, and initiate real time quality control like atmosphere monitoring using gas sensors—all while improving safety.

Our team will help you choose the right gases and packaging, so you’re always using the right amount.

We’re ready to help you optimize your process and heat treatment furnace parameters.

Access training and expertise to improve safety for your team and in the communities around you.

No two facilities are the same. Get gas equipment designed specifically for you, including:

Get started. Contact us today by requesting a follow-up or calling 800-282-1524.

Download our brochure to see more information about our heat treatment solutions for manufacturing.

Download PDF

Learn about our process solution designed to answer specific requirements for low-pressure carburizing your parts.

Download PDF

Talk to an expert about your gases, hardgoods and safety needs.