The more you know from Miller Welding, the better your welds

Like all great innovators, Miller Welding is focused on a philosophy of continuous improvement when it comes to welding. That’s why they develop new welding technologies to improve their welding products and create informational resources to support weld operators of all skill levels. Stay up to date and well informed with the welding information below.

Also check out the Miller Welding Smart Shop.

GREAT WELDS START HERE

Talk to our specialists about welding equipment, gases or safety

View helpful resources for weld operators

What is a Good Weld?

What goes into a good weld? Find out how to consistently get proper bead size and height with this helpful poster. Identify common welding issues related to travel speed (too fast/too slow), arc (voltage too high/voltage too low) and amperage (too much/too little).

Miller Welding: Eliminate Back Purge in Stainless Steel Pipe Welding

Learn how to do stainless steel pipe welding with more precision in a third of the time with these expert tips from Miller.

See more Miller Welding videos in the Miller Video Library

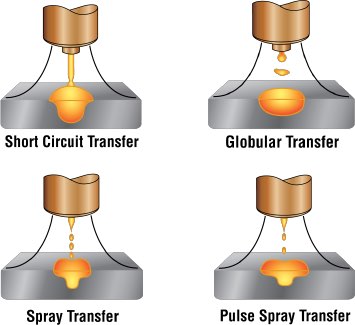

MIG Processes

When it comes to choosing the right MIG transfer process for your application, there are many variables to consider. How thick is the metal? How important is a good bead? How will the final product be used? Get answers with this handy guide.

View Miller Welding's MIG Process Guide (PDF)

GMAW-P (Pulsed MIG)

Scenario: A baseline weld was made using automated welding equipment. Voltage, wire feed speed, travel speed and contact-tip-to-work distance were then adjusted individually from baseline weld settings to illustrate how each parameter affects a fillet weld when raised and lowered. See the results in this simple breakdown.

View Miller Welding's GMAW-P Guide (PDF)Access more guidance from Miller Welding & Airgas on our blog—Airgas Thinks

How to Select a MIG Gun

How to Select a MIG Gun

MIG welding is among the easiest welding processes to learn and is useful for a variety of applications. Since the welding wire constantly feeds through … Read More

Finding the Right Shielding Gas for the Job

Finding the Right Shielding Gas for the Job

Just as the metals and processes that welders use vary from project to project, so do the gases they use. Shielding gases are an important … Read More

Welding Efficiency Analysis: Like Blood Tests for Your Business

Welding Efficiency Analysis: Like Blood Tests for Your Business

Take a look at how a welding efficiency analysis can help you ensure that all aspects of your welding operations are functioning as they should. … Read More

MIG Busters: Are You Using the Wrong Size MIG Wire?

MIG Busters: Are You Using the Wrong Size MIG Wire?

One of the many things to choose in MIG welding is the size of MIG wire you want to use. There is a widely accepted point of view that “thin” metal should … Read More

Troubleshooting Weld Defects to Save Time & Money

Troubleshooting Weld Defects to Save Time & Money

Like any part of the manufacturing or fabrication process, welding is subject to human error from time to time. When … Read More

Overcoming Barriers that Prevent Using Wire for Field Welding

Overcoming Barriers that Prevent Using Wire for Field Welding

When choosing the appropriate welding process for your jobsite, there’s a lot to consider. Application, weld position, material, procedures … Read More

Understanding the Basics of Metal-Cored Wire

Understanding the Basics of Metal-Cored Wire

In the right welding applications, metal-cored wire can minimize costs, improve quality and increase productivity. Like any filler metal, it … Read More

Aluminum Filler Metals: Selection, Characteristics & More

Aluminum Filler Metals: Selection, Characteristics & More

From its strength and versatility to its corrosion resistance, the benefits of aluminum are appealing for a variety of industries. … Read More