A Powermax user saves time on secondary grinding by using FlushCut consumables to cut within a quarter inch of the base. Photo courtesy of Hypertherm.

Cut closer than ever before

Close cutting applications like lug and attachment removal are easy—all you need is a Powermax® or Powermax SYNC™ system and FlushCut™ consumables. Learn why the Hypertherm flush cutting process is more effective than carbon arc gouging and other traditional methods for tasks like:

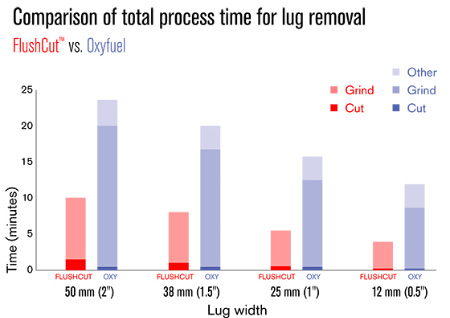

With carbon arc gouging, the weld needs to be removed on both sides, requiring multiple passes and additional time on the job. The Powermax flush cutting process allows operators to remove lugs and attachments in a single cutting pass. Flush cutting with plasma is also a quieter and less smoky process, which can improve the overall industrial hygiene of any shop or yard.

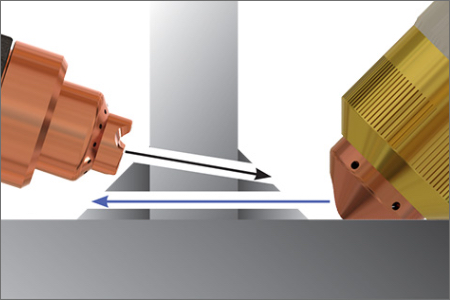

This diagram demonstrates how FlushCut consumables allow Powermax users to cut closer to the base than traditional plasma cutting.

The patented geometry of FlushCut consumables places the plasma arc in the ideal location for flush removals when compared to the arc delivery of a standard plasma cutting process. The optimized arc delivery with FlushCut consumables results in less post secondary grinding and material repairs.

GREAT CUTTING STARTS HERE

Talk to our specialists about welding equipment, gases or safety.