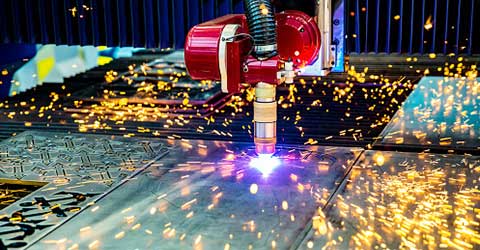

Maintain your cutting equipment with mechanized cutting services from Airgas, an Air Liquide company

Lack of preventive maintenance and running to failure will result in unplanned equipment downtime. That’s time wasted instead of spent manufacturing the products your customers depend on you to produce. In addition to unexpected equipment failures, poorly maintained machines and operator errors can also affect your productivity. Since running an efficient production schedule directly impacts your performance, keeping your equipment running and operators trained to use it properly is just as important as maintaining the rest of your business.

Talk to an expert about your gases, hardgoods and safety needs.

What are your challenges?

The Advanced Fabrication experts at Airgas includes a team of skilled technicians with specialized knowledge in servicing mechanized cutting equipment. Our technicians are OEM-certified and ready to help you develop a preventive maintenance plan to avoid running to failure so you keep your equipment operating. Additionally, we offer scheduled and emergency service to diagnose and repair equipment that has failed. Airgas also offers custom-engineered solutions and training to ensure your cutting system and operators are as efficient as possible.

Lack of equipment maintenance can cost you millions of dollars in downtime.

Jonathan White, National Sales & Operations Manager — Cutting Services

“Lack of equipment maintenance can cost you millions of dollars in downtime. Proactively maintaining your cutting equipment can significantly reduce the number of emergency service calls you make each year. Airgas offers a variety of services, including preventive maintenance, training and upgrading your existing machine with the newest technology, giving new life to your older equipment. Our technicians can assist you with maintaining your equipment, training operators and optimizing your productivity.”

As part of our mechanized cutting service program, we offer a range of services and training opportunities for plasma and oxy-fuel systems, including pipe profiling and bevel cutting machines.

Mechanized Cutting Services

Keep your cutting equipment running. Find out more about preventive maintenance and repair services and solutions offered by our cutting services team.

Download the Brochure

RADNOR Showcase

Discover everything you need to know about RADNOR hardgoods, consumables and safety products — all in one convenient location.

Visit our RADNOR Showcase

ESAB® Showcase

Get more information about our ESAB portfolio. Take advantage of current promotions and shop products from all of the ESAB brands.

Visit our ESAB Showcase