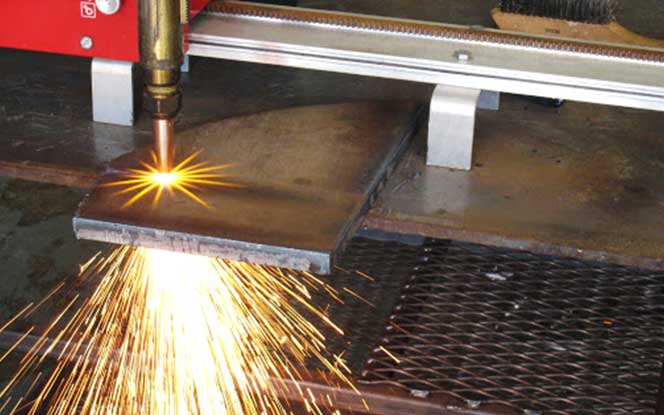

Execute a clean cut with gases, equipment, consumables and expertise from Airgas, an Air Liquide company

Operate at peak efficiency

Being able to accurately cut materials is one of the keys to keeping your production flowing. An inefficient process, unexpected equipment failure or other maintenance emergency brings both unhappy customers and lost profits. To avoid unplanned downtime and ensure your production stays on schedule, you need a reliable computer numerical control (CNC) cutting system that meets your specific needs and can deliver the precise cuts you want. Whether you’re performing a plasma, laser or oxy-fuel cutting application, you need solutions that deliver the high quality performance you require.

Talk to an expert about your gases, hardgoods and safety needs.

What are your challenges?

With more than 40 years experience in the metal fabrication industry, Airgas provides the cutting gases, equipment, consumables and process expertise for any cutting application. In addition, we have a comprehensive service offer, including periodic maintenance, retrofitting, installation and equipment location. We are dedicated to helping our customers grow their business by finding and implementing cost-saving programs. In fact, we’ve developed an entire program built around helping our customers be more competitive via sustainable cost reductions. The Unlocking the Hidden Cost of Welding™ program does just that, starting with a thorough Welding Efficiency Analysis™ to help you analyze and benchmark your current performance as compared to your peers. Additionally, our 10 Advanced Fabrication application centers located across the country allow us to provide demo, testing and training opportunities to further support your efforts to remain competitive.

Making the best decisions concerning your cutting equipment is critical to keeping your production going. Can you guess what we’ve learned about cutting equipment in a typical manufacturing facility?

Nothing gets welded until something gets cut.

Bill Pharmer, National Director Advanced Fabrication Technologies

“Nothing gets welded until something gets cut. Whether it’s plasma, oxy-fuel, laser or mechanical, accuracy of the cuts and the fit up of those parts greatly impact the overall productivity of any welding operation.”

Gases for cutting in a variety of supply modes

Hardgoods and consumables for cutting from various manufacturers, including RADNOR™

Process expertise from our team of Advanced Fabrication experts to address any application challenge

Cutting equipment from all the leading manufacturers plus 10 Advanced Fabrication centers across the U.S. with testing, demo and application development capabilities as well as cutting services, including equipment installation, training, retrofitting, service and preventive maintenance

Solutions, products and expertise that help improve safety for metal fabrication

Supply chain solutions for visibility, control and savings

Mechanized Cutting Services

Keep your cutting equipment running. Find out more about preventive maintenance and repair services and solutions offered by our cutting services team.

Download the Brochure

LaserPLUS™ Gases

To meet the precise and consistent purity specifications needed for optimal laser performance and tolerance, we produce our LaserPLUS gases under the strictest quality control.

Download the Brochure

Unlocking the Hidden Cost of Welding

Hear our customers describe their Unlocking the Hidden Cost of Welding class experience and how it’s changed the way they see their business.

Watch video

RADNOR Showcase

Discover everything you need to know about RADNOR hardgoods, consumables and safety products — all in one convenient location.

Visit our RADNOR Showcase

Hypertherm® Showcase

Discover what Hypertherm has to offer in cutting. From equipment to consumables and accessories, we’ve got the whole collection right here.

Visit our Hypertherm Showcase

ESAB® Showcase

Get more information about our ESAB portfolio. Take advantage of current promotions and shop products from all of the ESAB brands.

Visit our ESAB Showcase