Protect your team with safety solutions, products and services from Airgas, an Air Liquide company

The best way to stay safe is to be aware of the hazards around you and then do what you can to control them. To a great extent, many safety risks are completely manageable and unsafe situations can be avoided altogether. And while all safety risks can’t be avoided, there are safety procedures that can be implemented to make them less of a threat. By considering all the different aspects of safety in your facility and on your shop floor, you can develop a plan suited for your workplace to protect the safety of your team. We’re also focused on addressing the unique challenges women welders and fabricators face when using ill-fitting PPE. Check out this article from The Welder to see how we're Narrowing the welding PPE gap for women in fabrication.

Please complete the form to connect with an expert at Airgas.

Talk to an expert about your gases, hardgoods and safety needs.

What are your challenges?

As a company that makes safety its first priority, Airgas supports you in every aspect when it comes to safety in your own organization. We believe strongly in the importance of adopting a complete safety program that helps you eliminate risks and protect your team from the hazards you can’t avoid. We’re aligned with the principle of managing risks known as the Hierarchy of Controls and will work with you to help you implement a safety program that applies this method to your business.

At Airgas, safety is the air we breathe and the foundation of everything we do.

Marie Anstead, Vice President — Health, Safety, Environment & IMS

“At Airgas, safety is the air we breathe and the foundation of everything we do. Our commitment to delivering the most reliable and secure industrial gas supply ensures that our customers can operate with confidence and peace of mind. We go beyond compliance, setting new standards in safety and quality, because we believe that protecting lives and empowering industries to respect safety compliance are inseparable. Trust in Airgas means trusting in unparalleled safety, innovation, and excellence, every step of the way.”

Read more about welding and cutting safety standards and guidelines

Get information about methods, including fume extraction and wearing the proper PPE, that help protect against safety hazards associated with hexavalent chromium

Head-to-toe safety products and PPE

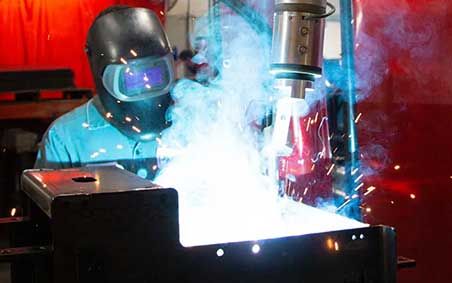

Whether you're welding, cutting or using automation, safety products and PPE are essential to help you get the job done.

For welding

See the products you need to stay protected

For plasma cutting

See the products you need to stay protected

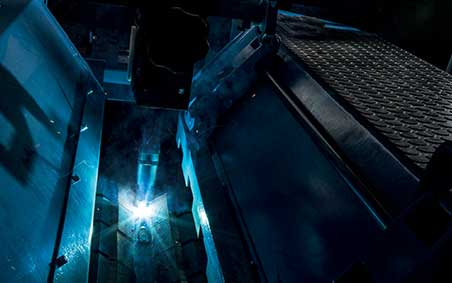

For automation

See the products you need to stay protected

For robotics

See the products you need to stay protected

Welding Safety Products

Get the welding safety products you need to protect your team as they work.

Shop the Collection

PPE Gap for Women in Fabrication

Learn more about the unique challenges women face when using ill-fitting PPE in this article from The Welder.

Read the Article

Airgas Safety Solutions

Learn amore about our safety products and services and what Safety Beyond Products means for you.

Explore our Safety Offer

iMSafe™ Safety Assessment

Discover how a safety assessment performed on your site by an Airgas safety specialist can help you identify workplace risks and hazards.

Learn about iMSafe